CIP Performance Starts With Piping and Infrastructure

Clean-in-Place (CIP) systems are often evaluated based on skid size, automation level, or chemical selection. In practice, many CIP performance issues have little to do with the skid itself. Instead, they originate in piping layout, infrastructure decisions, and how the CIP system is integrated into the broader process.

In beverage and liquid processing facilities, CIP reliability is directly tied to how effectively cleaning solutions can be delivered, circulated, and removed. When piping and infrastructure are not designed with cleanability in mind, even well-designed CIP equipment will underperform.

CIP Is an Integrated System, Not a Standalone Skid

CIP systems do not operate in isolation. They rely on process piping, valves, tanks, utilities, and controls working together as a coordinated system. When those elements are designed independently—or added incrementally over time—cleaning efficiency often suffers.

Common indicators of integration issues include:

- CIP cycles that take longer than expected

- Inconsistent cleaning results between circuits

- Manual flushing or operator intervention

- Difficulty validating or repeating CIP performance

Common CIP Piping and Infrastructure Mistakes

1. Poor Drainability

Inadequate pipe slope, unnecessary elevation changes, and low points can trap product or cleaning solutions. These conditions dilute chemicals, extend rinse times, and increase the risk of residual contamination.

2. Pipe Sizing Based Only on Process Flow

Process piping is frequently sized for production transfers rather than CIP requirements. Cleaning often demands higher velocities than normal operation, and undersized lines limit mechanical cleaning action.

3. Valve Placement That Creates Dead Legs

Improperly located manual valves, sample ports, or unused branches can create areas that receive little to no CIP flow. Over time, these dead legs become reliability and quality risks.

4. Inconsistent CIP Circuit Design

Facilities that grow over time often accumulate CIP circuits with varying diameters, lengths, and return paths. Without standardization, cleaning results become unpredictable and difficult to optimize.

Access, Serviceability, and Long-Term Reliability

CIP systems must be serviceable to remain reliable. Limited access to valves, instruments, or piping connections makes routine inspection and troubleshooting more difficult, increasing downtime when issues arise.

Well-integrated systems account for:

- Clear access to critical components

- Logical routing that supports troubleshooting

- Consistent circuit design for repeatable results

Evaluating the Full CIP Ecosystem

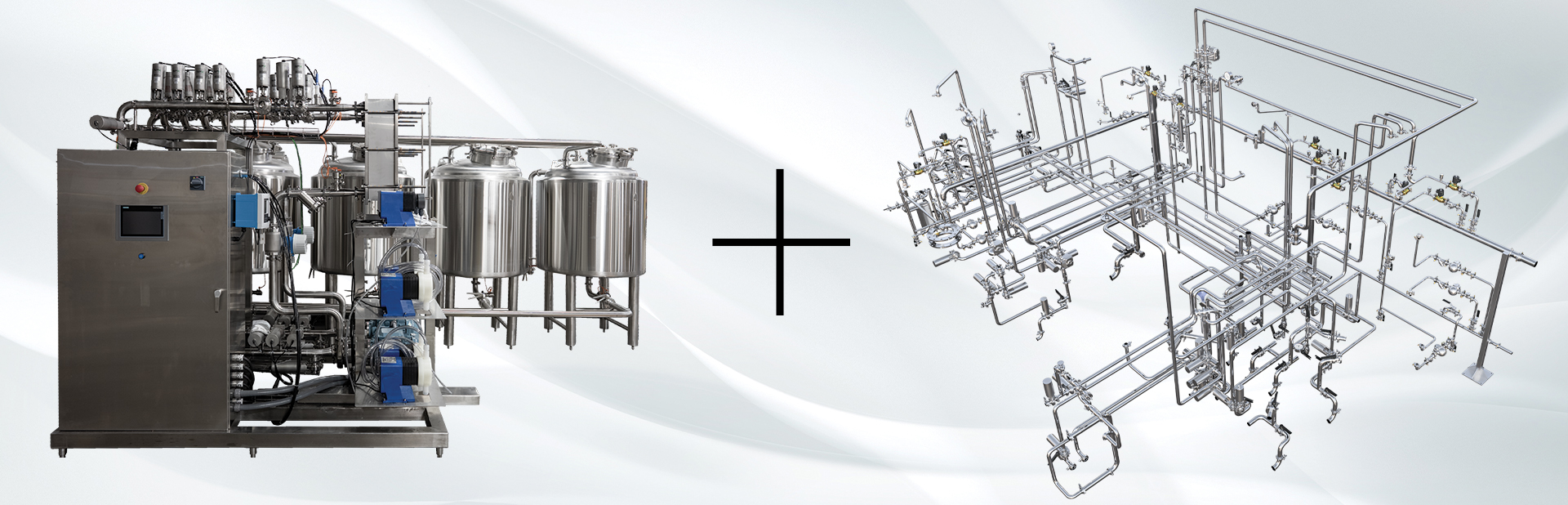

While many CIP challenges stem from piping and infrastructure, the CIP skid or cart still plays an important role in the overall system. The key is selecting and configuring cleaning equipment in the context of the facility it supports.

In addition to system integration and piping design, Deutsche engineers and supplies a range of standardized and custom CIP skids and carts. Evaluating the full CIP ecosystem—piping, vessels, utilities, and cleaning equipment—allows the appropriate solution to be matched to each facility’s needs.

Taking a system-level view helps ensure CIP performance supports consistent cleaning, predictable cycle times, and sustained uptime as operations evolve.

Frequently Asked Questions: CIP Piping Design

Most CIP issues are caused by piping layout, drainability, dead legs, or undersized lines that limit cleaning velocity. Even a properly designed CIP skid cannot overcome poor piping infrastructure.

Poor CIP piping design can extend cleaning cycles, require manual intervention, and lead to inconsistent cleaning results. Over time, this reduces available production time and increases operational downtime.

Common mistakes include inadequate pipe slope, piping sized only for process flow, valve placement that creates dead legs, inconsistent CIP circuits, and limited access for inspection and maintenance.

Yes. Many CIP performance issues can be resolved by correcting piping layout, improving drainability, eliminating dead legs, or rebalancing CIP circuits—without changing the CIP skid itself.

Facilities should review CIP flow velocities, drainage points, valve placement, circuit consistency, and service access. A system-level evaluation often identifies infrastructure constraints affecting cleanability and uptime.

Summarized Article

CIP Performance Starts With Piping and Infrastructure

Clean-in-Place (CIP) systems are often evaluated based on skid size, automation level, or chemical selection. In practice, many CIP performance issues have little to do with the skid itself. Instead, they originate in piping layout, infrastructure decisions, and how the CIP system is integrated into the broader process.

CIP Is an Integrated System, Not a Standalone Skid

CIP systems do not operate in isolation. They rely on process piping, valves, tanks, utilities, and controls working together as a coordinated system. When those elements are designed independently—or added incrementally over time—cleaning efficiency often suffers.

Common CIP Piping and Infrastructure Mistakes

– Poor drainability

– Pipe sizing based only on process flow

– Valve placement that creates dead legs

– Inconsistent CIP circuit design

Evaluating the Full CIP Ecosystem

While many CIP challenges stem from piping and infrastructure, the CIP skid or cart still plays an important role in the overall system. Deutsche designs and supplies both standardized and custom CIP skids and carts, evaluating the entire CIP ecosystem to match each facility with the appropriate solution.