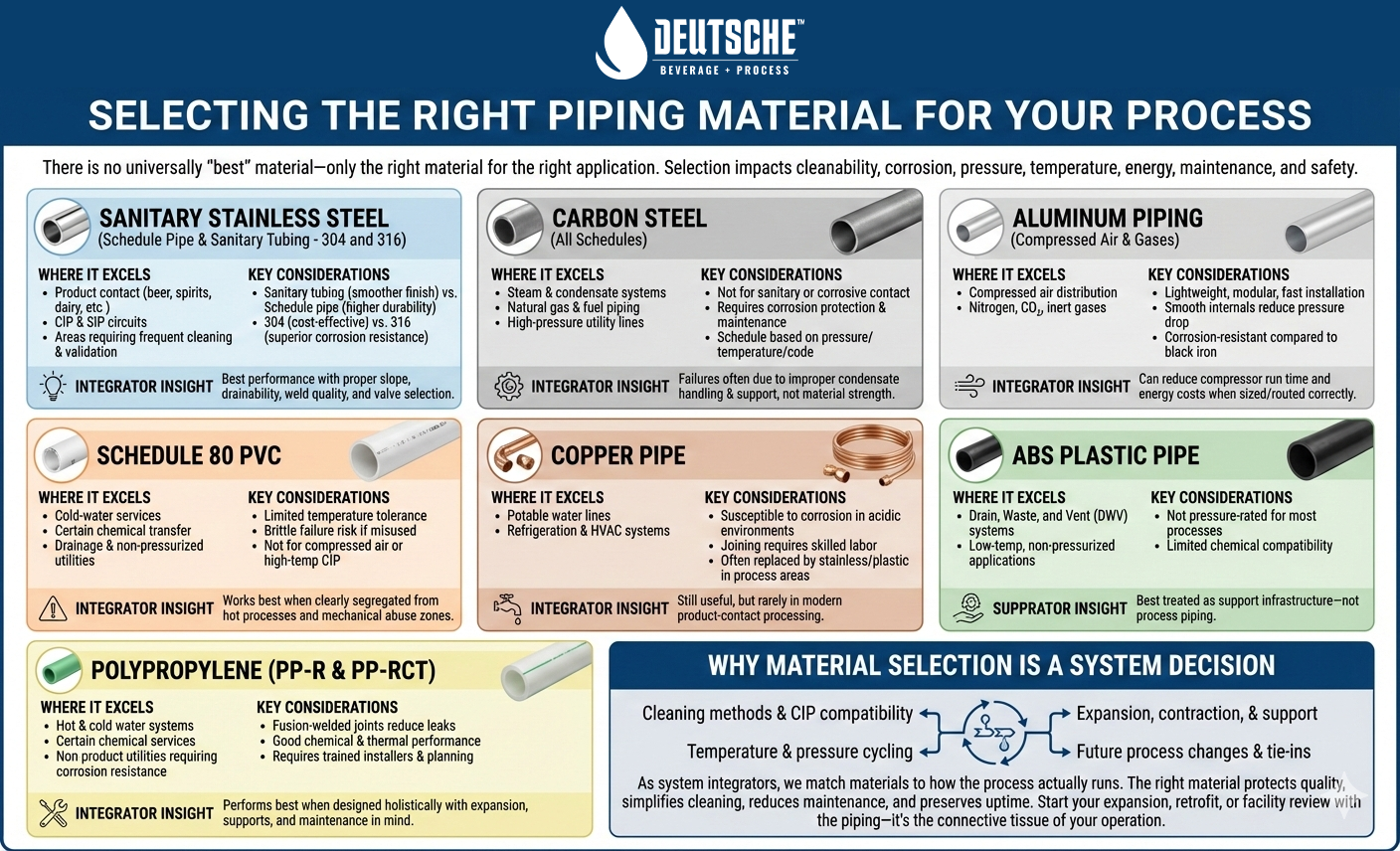

When it comes to process piping, there is no universally “best” material—only the right material for the right application. Each piping option brings its own strengths, limitations, and ideal use cases, and understanding those differences is critical to how your facility operates day to day.

Material selection affects far more than installation cost. It influences cleanability, corrosion resistance, pressure and temperature limits, energy efficiency, maintenance requirements, safety, and how easily your plant can adapt as products or volumes change. A material that performs well in one part of the process can become a liability in another if its limits aren’t fully understood.

For co-packers, beverage producers, and processing facilities running a mix of products and utilities, selecting piping materials isn’t just an engineering exercise—it’s a process decision. Evaluating the pros, cons, and proper applications of each material early helps prevent quality issues, premature wear, and costly retrofits later, while ensuring the piping system supports how the plant actually runs today—and how it may need to run tomorrow.

Sanitary Stainless Steel (Schedule Pipe & Sanitary Tubing – 304 and 316)

Sanitary stainless steel is the backbone of most food, beverage, and hygienic processing environments.

Where it excels

- Product contact piping for beer, spirits, carbonated beverages, RTDs, coffee, tea, dairy, and other hygienic liquids

- CIP and SIP circuits

- Areas requiring frequent cleaning, inspection, and validation

Key considerations

-

Sanitary tubing vs. schedule pipe:

- Sanitary tubing offers smoother internal finishes and better cleanability.

- Schedule pipe provides higher wall thickness and structural durability, often used in utility or hybrid applications.

-

304 vs. 316 stainless:

- 304 is cost-effective for many beverage applications.

- 316 offers superior corrosion resistance, especially where chlorides, acids, or aggressive CIP chemistries are present.

Integrator insight: Stainless systems perform best when slope, drainability, weld quality, and valve selection are designed together—not pieced together over time.

Carbon Steel (All Schedules)

Carbon steel remains a workhorse for non-product utilities and high-pressure services.

Where it excels

- Steam and condensate systems

- Natural gas and fuel piping

- High-pressure utility lines

Key considerations

- Not suitable for sanitary or corrosive product contact

- Requires proper corrosion protection, insulation, and maintenance

- Schedule selection must account for pressure, temperature, and code requirements

Integrator insight: Carbon steel failures often come from improper condensate handling and support—not material strength.

Aluminum Piping (Compressed Air & Gases)

Modern aluminum piping systems have become popular alternatives to traditional steel air lines.

Where it excels

- Compressed air distribution

- Nitrogen, CO₂, and other inert gases

Key considerations

- Lightweight and modular, allowing faster installation

- Smooth internal surfaces reduce pressure drop and energy loss

- Corrosion-resistant compared to black iron

Integrator insight: Aluminum air systems can quietly reduce compressor run time and energy costs when sized and routed correctly.

Schedule 80 PVC

Schedule 80 PVC offers chemical resistance at a lower material cost—but with limits.

Where it excels

- Cold-water services

- Certain chemical transfer lines

- Drainage and non-pressurized utilities

Key considerations

- Limited temperature tolerance

- Brittle failure risk if misused

- Not suitable for compressed air or high-temperature CIP

Integrator insight: PVC works best when it’s clearly segregated from hot processes and mechanical abuse zones.

Copper Pipe

Copper has a long history in food and beverage facilities, though its role has narrowed.

Where it excels

- Potable water lines

- Refrigeration and HVAC systems

Key considerations

- Susceptible to corrosion in acidic or aggressive environments

- Joining methods require skilled labor

- Often replaced by stainless or plastic in modern processing areas

Integrator insight: Copper still has a place—but rarely in modern product-contact processing.

ABS Plastic Pipe

ABS is lightweight and impact-resistant, typically used in non-critical services.

Where it excels

- Drain, waste, and vent (DWV) systems

- Low-temperature, non-pressurized applications

Key considerations

- Not pressure-rated for most process applications

- Limited chemical compatibility

Integrator insight: ABS is best treated as support infrastructure—not process piping.

Polypropylene (PP-R & PP-RCT)

Polypropylene piping systems are gaining traction in processing environments.

Where it excels

- Hot and cold water systems

- Certain chemical services

- Non-product utilities requiring corrosion resistance

Key considerations

- Fusion-welded joints reduce leak points

- Good chemical resistance and thermal performance

- Requires trained installers and proper planning

Integrator insight: PP-R systems perform best when designed holistically with expansion, supports, and long-term maintenance in mind.

Why Material Selection Is a System Decision

The biggest piping issues we see rarely come from a single bad material choice. They come from mixing materials without considering:

- Cleaning methods and CIP compatibility

- Temperature and pressure cycling

- Expansion, contraction, and support

- Future process changes and tie-ins

As system integrators, our role is to help facilities match piping materials to how the process actually runs—not just what looks good on a spec sheet.

Engineering Piping Decisions That Protect Uptime

The right piping material does more than move product from point A to point B. It protects product quality, supports effective cleaning, reduces long-term maintenance, and keeps production running as planned. The wrong choice, on the other hand, often introduces hidden risks—premature wear, sanitation challenges, unplanned downtime, and costly rework that compounds over time.

This is where experience matters. Deutsche Beverage + Process approaches piping material selection as part of a fully integrated system, not a standalone install. Our team evaluates how materials interact with your processes, utilities, CIP methods, operating schedules, and future expansion plans—so piping supports the way your facility actually runs.

Whether you’re planning an expansion, a retrofit, or a facility-wide review, starting with the piping allows issues to be identified early, changes to be staged intelligently, and production to stay online. Treated with the same level of engineering rigor as tanks, skids, and automation, piping becomes a long-term asset rather than a recurring problem.

Frequently Asked Questions: Choosing the Right Piping Materials

Start by evaluating application, temperature, pressure, cleanability requirements, chemical exposure, and whether the line is product-contact or utility. No single material works everywhere. Many facilities use multiple materials—stainless for product and CIP, carbon steel or aluminum for utilities, and plastics for specific water or drain services. The goal is matching each material to how that part of the system actually operates.

Sanitary tubing is designed for cleanability and hygienic service, with smoother internal finishes and consistent wall thickness—ideal for product and CIP lines. Schedule pipe has thicker walls and is often used where structural strength or higher pressures are needed. The right choice depends on whether cleanliness, pressure, or durability is the driving requirement.

Yes—and most facilities do—but it must be done intentionally. Mixing materials without considering thermal expansion, corrosion, cleaning methods, and connection details often leads to leaks, sanitation issues, or premature failures. A coordinated design ensures transitions between materials are safe, serviceable, and code-compliant.

Plastic piping can be effective for non-product utilities, water services, drains, or certain chemical applications, depending on temperature and pressure limits. However, plastics are generally not appropriate for product-contact or high-temperature CIP. Understanding where plastics add value—and where they introduce risk—is key.

Material selection affects far more than the pipe itself—it impacts CIP performance, uptime, maintenance, safety, and future expansion. A system integrator like Deutsche Beverage + Process evaluates piping as part of the entire process ecosystem, helping facilities avoid costly rework and ensuring the system supports both current operations and long-term growth.

Summarized Article

Selecting the right piping material is crucial for process efficiency, safety, and sanitation. Stainless steel, carbon steel, aluminum, PVC, copper, ABS, and polypropylene each serve specific roles. Proper selection considers product contact, temperature, pressure, cleanability, and future process adaptability.

What Are the Best Materials for Process Piping?

Choosing piping material isn’t about finding the “best” option universally—it’s about selecting what suits your facility’s needs. Material choice impacts:

-

Product safety and sanitation

-

Corrosion resistance and chemical compatibility

-

Pressure and temperature tolerance

-

Energy efficiency and maintenance requirements

-

Plant adaptability for future process changes

A material that excels in one area may fail in another if its limits are not understood. Early evaluation prevents retrofits, contamination, and downtime.

Why Sanitary Stainless Steel Is a Top Choice

Applications:

-

Product-contact lines for beer, spirits, RTDs, coffee, tea, and dairy

-

Clean-in-place (CIP) and sterilization-in-place (SIP) circuits

-

Areas requiring frequent inspection and validation

Material Options:

-

304 Stainless Steel: Cost-effective for most beverage systems

-

316 Stainless Steel: Superior corrosion resistance for chlorides, acids, and aggressive CIP chemicals

Form Factors:

-

Sanitary Tubing: Smooth interior, optimal cleanability

-

Schedule Pipe: Higher wall thickness, durable, often used in utilities

Pro Tip: System performance depends on slope, drainability, weld quality, and valve selection—avoid ad-hoc designs.

When to Use Carbon Steel

Best For:

-

Steam and condensate

-

Natural gas and fuel piping

-

High-pressure utility lines

Considerations:

-

Not suitable for product contact

-

Requires corrosion protection, insulation, and careful support

-

Schedule selection must meet pressure and code requirements

Integrator Insight: Most failures result from improper condensate management, not material strength.

Aluminum Piping: Lightweight and Efficient

Applications:

-

Compressed air

-

Inert gases like nitrogen or CO₂

Advantages:

-

Lightweight, modular, quick installation

-

Smooth internal surface reduces pressure drop

-

Corrosion-resistant

Energy Insight: Proper routing and sizing reduce compressor runtime and energy costs.

Schedule 80 PVC: Affordable Chemical Resistance

Best For:

-

Cold water lines

-

Certain chemical transfers

-

Drainage and non-pressurized utilities

Limitations:

-

Low temperature tolerance

-

Brittle under mechanical stress

-

Unsuitable for high-temperature CIP

Tip: Keep PVC away from hot or high-abuse zones to prevent failure.

Copper Pipe: Historical but Limited

Uses:

-

Potable water

-

HVAC and refrigeration systems

Considerations:

-

Corrosion in acidic environments

-

Skilled labor required for joining

-

Often replaced by stainless or plastic for product-contact lines

Insight: Copper remains viable mainly for utility services.

ABS Plastic: Support Infrastructure Only

Uses:

-

Drain, waste, vent (DWV) systems

-

Low-pressure, low-temperature lines

Limitations:

-

Not suitable for pressurized processes

-

Limited chemical resistance

Pro Tip: Treat ABS as infrastructure, not process piping.

Polypropylene (PP-R & PP-RCT): Modern Utility Choice

Applications:

-

Hot and cold water

-

Certain chemical services

-

Corrosion-resistant non-product utilities

Benefits:

-

Fusion-welded joints minimize leaks

-

Excellent chemical and thermal resistance

Installer Insight: Holistic design—including expansion, supports, and maintenance planning—ensures longevity.

Why Piping Selection Is a System Decision

Mixing materials without system-level planning causes most failures. Consider:

-

CIP methods and chemical compatibility

-

Pressure and temperature cycles

-

Expansion, contraction, and support needs

-

Future process tie-ins

Key Idea: Integrators align material selection with how the process actually runs, not just what looks good on paper.

Engineering Decisions That Protect Uptime

Correct material choice ensures:

-

Product quality and sanitation

-

Reduced long-term maintenance

-

Continuous production

Wrong choices can lead to hidden risks like unplanned downtime, premature wear, and costly rework. Treat piping like tanks or automation: a long-term asset, not a temporary fix.