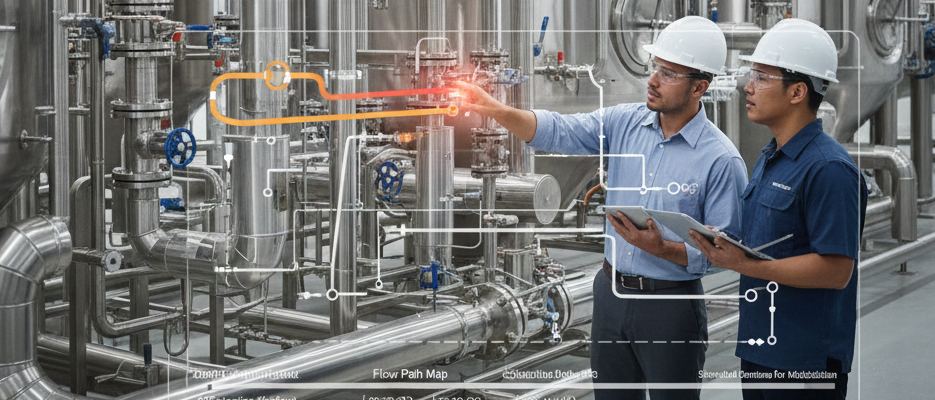

In many beverage and liquid processing facilities, the need to modify or expand process piping doesn’t come with the luxury of extended downtime. Whether it’s adding new tanks, integrating a skid, improving CIP performance, or correcting legacy piping issues, the challenge is the same: how to make changes without disrupting ongoing production.

Successful piping modifications start with planning that treats the facility as a living system, not a static installation. Understanding how product moves, how cleaning cycles are executed, and where operational bottlenecks already exist allows modifications to be phased, isolated, and executed with minimal risk to uptime.

Start With Flow Paths and Operating Windows

Before any pipe is cut or rerouted, it’s critical to map active flow paths and identify when those lines are actually in use. Many facilities have predictable production rhythms that create opportunities for short, controlled tie-ins. Planning modifications around these windows can eliminate the need for full shutdowns.

- When planning live modifications, teams should account for:

- Active product flow paths and shared transfer lines

- CIP schedules and cleaning windows

- Tank turnovers, batching, and packaging timing

- Shared utilities that could impact multiple processes

Equally important is identifying shared utilities and CIP circuits. A single overlooked connection can unintentionally take multiple processes offline if isolation isn’t designed in advance.

Design for Isolation, Not Just Expansion

One of the most common mistakes in live-facility modifications is focusing only on the new piping, without considering how it will be isolated during installation and future maintenance. Adding strategically placed components allows work to happen on one section of the system while the rest of the plant continues to operate.

- Effective isolation planning often includes:

- Strategically placed manual or automated valves

- Temporary bypasses for active production lines

- Capped take-offs for future expansion

This approach doesn’t just protect uptime during construction—it also improves long-term flexibility for future expansions, maintenance, and troubleshooting.

Prefabrication and Modular Thinking Reduce Risk

Whenever possible, fabricating piping sections, manifolds, or skid connections off-site dramatically reduces on-site work time. Modular assemblies can be installed quickly during short downtime windows, minimizing disruption and improving weld quality and consistency.

- Facilities that use modular piping strategies benefit from:

- Shorter installation timelines

- Improved weld quality and consistency

- Cleaner layouts that scale more easily over time

For facilities planning multiple upgrades over time, modular piping strategies allow easier adaptation as production needs evolve.

Cleanability Can’t Be an Afterthought

Maintaining CIP effectiveness during live modifications is critical. New piping must be evaluated for slope, drainability, and cleaning velocity—especially when tying into legacy systems.

- Common cleanability issues introduced during live modifications include:

- Dead legs created by poorly placed branches or valves

- Insufficient slope preventing full drainage

- CIP coverage gaps caused by improper flow velocities

A modification that preserves uptime but compromises cleanability will quickly create larger operational problems.

Experience Matters in Live Environments

Working in an active production facility requires more than fabrication skill—it requires process awareness. Knowing how to sequence work, coordinate withoperators, and anticipate how small changes affect the broader system is what allows piping modifications to happen smoothly without unexpected downtime.

When process piping is planned with production realities in mind, facilities can evolve and improve without hitting pause on output—protecting both product quality and profitability.

Frequently Asked Questions: CIP Piping Design

Yes. With proper planning, piping modifications can often be completed while production continues. This is typically done by identifying unused operating windows, isolating sections of piping with valves or temporary bypasses, and sequencing tie-ins to avoid disrupting active processes.

The biggest risk is unintentionally affecting shared systems such as CIP circuits, utilities, or transfer lines. Without proper isolation planning, a single modification can take multiple processes offline or compromise cleaning effectiveness.

Downtime is minimized by prefabricating piping assemblies off-site, planning tie-ins around CIP or tank turnover windows, and using modular designs that can be installed quickly during short production pauses.

Any new piping must maintain proper slope, drainability, and flow velocity for effective CIP. Poorly planned modifications can introduce dead legs or cleaning gaps, leading to contamination risk and longer-term operational issues.

A system integrator should be involved early in the planning phase. Their process knowledge helps ensure modifications are sequenced correctly, isolation strategies are built in, and production, cleaning, and future expansion needs are all considered.

Summarized Article

Process piping modifications can be executed without halting production when facilities plan around isolation, sequencing, and cleanability—treating piping as a dynamic system tied to operations, not static infrastructure.

Key principles for successful live modifications:

- Map active flow paths to understand how product, CIP, utilities, and schedules interact.

- Exploit operating windows such as tank turnovers, CIP cycles, and packaging pauses to perform tie-ins.

- Design for isolation using valves, bypasses, and capped take-offs so targeted sections can be modified independently.

- Prefabricate and modularize assemblies to reduce on-site labor, risk, and tie-in time.

- Preserve hygienic design—maintain slope, drainability, velocity, and dead-leg control to protect CIP effectiveness and product safety.

When planned with real production constraints and operator workflows in mind, live piping modifications enable facilities to expand capacity, correct issues, and improve long-term flexibility—without sacrificing uptime, quality, or reliability.