Enhance Flavors In Your Beer and Beverages

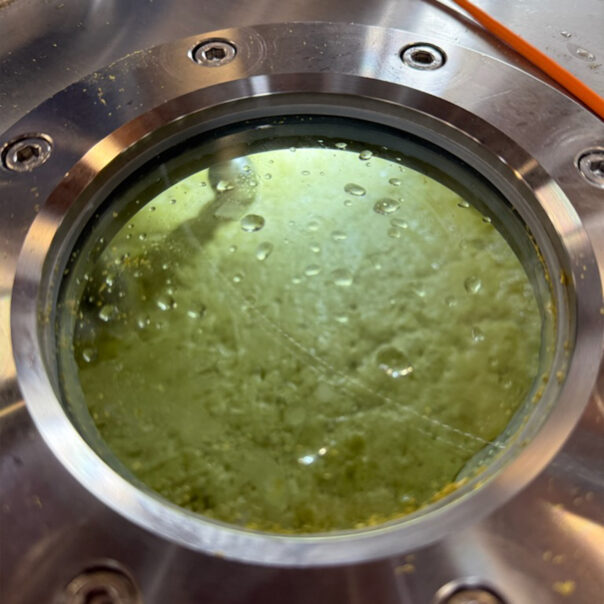

Infuse your beverages with a wide range of fresh, natural flavors to create unique and appealing products. Common infusion ingredients include hops, coffee and tea, fruits and botanicals, herbs and spices, syrups and flavors, and more.

- 5 HP SPX C-Series Centrifugal Pump

- 40rpm mixer

- CIP Spray ball assembly

- Mobile skid assembly with non-slip stairs and 304ss process piping

- Control Cabinet for Vessel Light, Mixer, and Pump VFD Controls

Enhance Flavors In Your Beer and Beverages

Infuse your beverages with a wide range of fresh, natural flavors to create unique and appealing products. Common infusion ingredients include hops, coffee and tea, fruits and botanicals, herbs and spices, syrups and flavors, and more.