Craft Brewing Equipment

Looking for truly customizable, turn-key, automated beer brewing systems? Deutsche brewing equipment is the answer. Our craft beer brewing systems cater to breweries of all sizes, ranging from 2 to 100 barrels. With our engineering-focused expertise in crafting high-quality equipment, we provide the tools and technology you need to streamline your brewing process and achieve exceptional results.Join the 100’s of award-winning breweries using Deutsche brewing equipment.

Custom Brewhouse

Limitless possibilities for those looking to perfect their exact brewing equipment, and process

- Custom piping and platform design

- Multiple vessel combinations

- Available grades of stainless 304-316

- Custom siemens control options

- Able to meet specific production goals

Pilot Brewhouse

Perfect your recipes on a pilot brewhouse before scaling up to your production system.

- Integration into production brewing system

- Consistency in scaling

- Custom siemens control options

- Layout variations to fit into current facility

- Starting at 2 Barrels production size

Pub Brewhouse

Perfect for those looking to enter the brewing space, i.e. start-up breweries, restaurants or bars.

- 2 – 10 barrel systems

- Multiple vessel configurations

- Able to fit your space with a custom platform and piping

Production Brewhouse

Perfect for the brewery looking to meet large production or distribution goals.

- Up to 100 Barrel Systems

- Engineered for ultimate efficiency of power and water usage

- Automation to reduce dependence on labor

Project Management Installation, and commissioning

Cellar Tanks and Vessels

Fermentation and conditioning tanks, customizable to specific sizes and dimensions. Designed and engineered to meet your production schedule.

- 2-240 barrel size options

- Jacketed or Unjacketed options

- Ability to integrate temperature controls

- CIP skid or other cleaning options available

Brewhouse Tanks

Individual brewhouse vessels customizable to meet your grain bill.

- Build into your current system

- Pressure and Temperature control options

- Efficient heat transfer system for optimal brewing conditions

- Designed to allow for flexibility in the brewing process

Tilting Hop Infuser

Easily and efficiently infuse a wide array of flavors into your food and beverage products.

- Custom skid-mounted designs up to 2500L

- Perfect for infusing and extracting with whole bean or ground coffee, tea, botanicals, spices, concentrates, syrups, fruit, and more

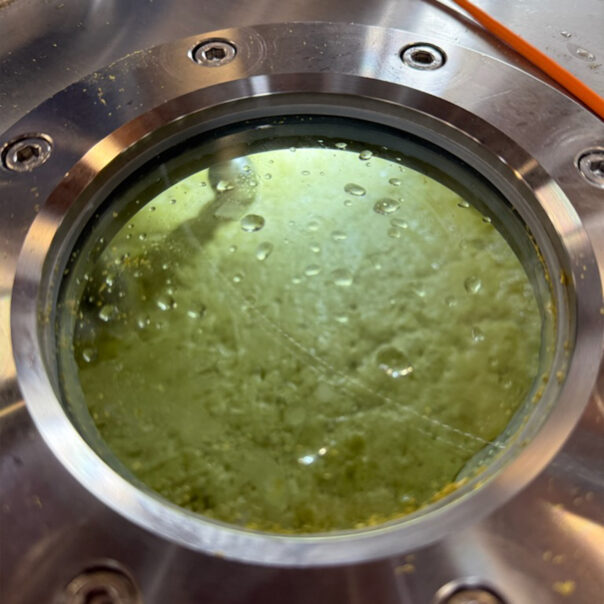

Brewers Infusion Vessel

Designed to optimize large-scale dry hopping. This system makes the hop infusion process safer, easier and more efficient. Consisting of a single-walled 5BBL mixing tank with hard piped 5hp pumps, VFD controlled mixing impeller, Co2 manifold, and other unique features. This can also incorporate other flavorings, adjuncts, or syrups.

Material Handling

Pre or post-processing material management

- Grain, coffee, hemp spent and raw material management

- Convenience systems and storage vessels to serve material management