Streamline cleaning processes and maintain sanitary production environments

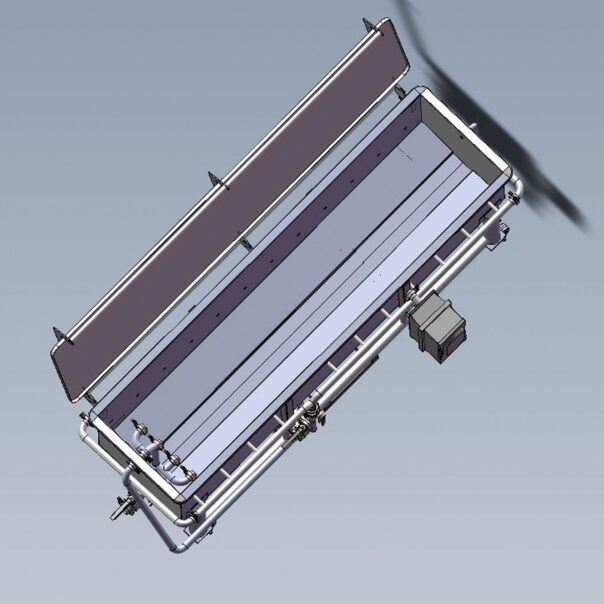

Our COP (Clean-Out-of-Place) Carts are designed for processors who demand high levels of cleanliness and efficiency in their sanitary workflows. These mobile units provide a reliable method for thoroughly cleaning small parts, fittings, hoses, and other components that can’t be cleaned in place. By enabling manual agitation with heated and chemically dosed wash solutions, COP carts help remove buildup and prevent contamination—ensuring compliance with hygiene standards across food, beverage, and pharmaceutical applications.

- Available sizes: 150G, 225G, 335G

- SPX C-216 pump (7.5 HP) with TECO washdown VFD

- 304 Stainless Steel tub and frame construction

- Integrated ¾” nozzle holes for directional jet cleaning

- Mobile cart design for flexible use across your facility

- Hose flushing attachment with TCP ports for internal cleaning

- Designed to operate with hot or ambient water (no built-in heat source)

- Compatible with caustic, sanitizing, or rinse solutions

What is a COP Cart and when should I use one?

The term “COP” stands for “Clean-Out-of-Place,” and it refers to the manual cleaning of equipment parts removed from the main processing system. COP Carts are mobile stainless steel units designed to soak and flush disassembled parts like hoses, fittings, and clamps using hot water or cleaning solutions. They are commonly used in food, dairy, and beverage industries where components cannot be effectively cleaned in place.

How does a COP Cart clean equipment parts?

COP Carts are equipped with powerful 7.5 HP pumps and integrated ¾” nozzle jets that circulate cleaning fluid around and through submerged parts. This high-impact cleaning process helps remove buildup, residues, or contaminants while soaking the components in hot water or a caustic solution for sanitation.

What industries use COP Carts?

COP Carts are commonly used in the food, dairy, nutraceutical, and some beverage production environments where equipment needs to be manually disassembled for cleaning. They’re especially helpful in operations with frequent product changeovers or in facilities that use a wide variety of hoses, valves, and fittings.

Can I clean hoses with a COP Cart?

Yes. Each COP Cart includes a built-in TCP port hose cleaning attachment that allows for internal flushing of sanitary hoses. Simply connect the hoses to the designated ports and circulate hot water or cleaning solution through them using the onboard pump.

Does the COP Cart have a heating element?

No. The COP Cart is designed without built-in heating elements, which keeps cost and complexity lower. It requires a hot water source to be filled manually or through an external supply. Custom heating options may be quoted if required for specific applications.

REQUEST A QUOTEStreamline cleaning processes and maintain sanitary production environments

Our COP (Clean-Out-of-Place) Carts are designed for processors who demand high levels of cleanliness and efficiency in their sanitary workflows. These mobile units provide a reliable method for thoroughly cleaning small parts, fittings, hoses, and other components that can’t be cleaned in place. By enabling manual agitation with heated and chemically dosed wash solutions, COP carts help remove buildup and prevent contamination—ensuring compliance with hygiene standards across food, beverage, and pharmaceutical applications.