Skid Mounted and Portable CIP Solutions

Skidded and portable CIP systems engineered to ultimate efficiency and thorough cleaning for tanks, equipment, and pipelines. Seamless integration into existing processing systems with customizable options to meet the unique needs of your brewing, craft beverage, food processing, co-packing, or other sanitary systems. Streamline operations, maximize efficiency, and minimize costs.

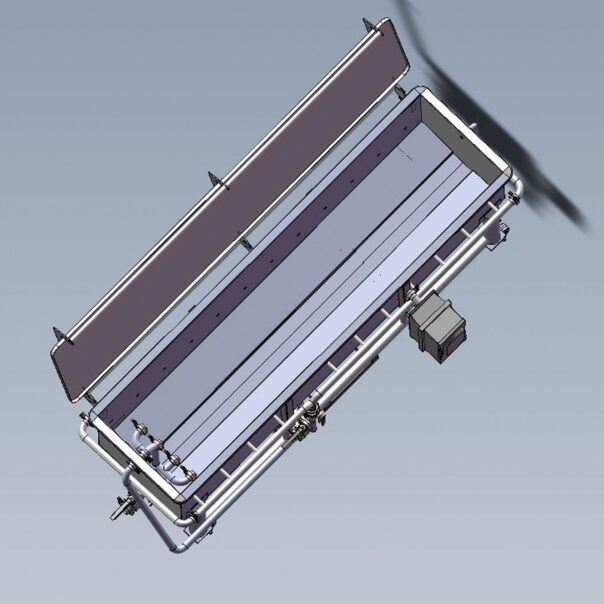

Waterless Clean in Place Skid (CIP)

A specialized clean-in-place system that uses a heated oil cleaning medium to deliver effective circulation and sanitation in processes where water introduction is restricted or where reducing the risk of waterborne pathogens is critical.

Automated Clean in Place Skid (CIP)

Industry-leading Clean In Place (CIP) technology, completely customizable

Clean Out of Place (COP) Cart

A mobile, high-impact cleaning solution for hoses, disassembled parts, and process equipment. Available in 150G, 225G, and 335G sizes, each unit features a powerful 7.5 HP pump and stainless steel construction for durable, repeatable sanitation.